MARVAPOL joint laboratory

The joint laboratory MARVAPOL (Laboratory of Advanced Recycled Materials by VAPOthermoLyse) between ARMINES, IMT Albi (Centre RAPSODEE and ICA) and ARC/AFRC (Alpha Recyclage Composites and Alpha reyclage Franché Conté) was created to initiate a multi-year research collaboration on the topic of recycling of tyres and carbon fibre composites by the vapothermolysis process. Vaporthermolysis is a process that uses superheated water vapour at room pressure to separate the matrix from the fibres, making it a low-cost and dry process.

The ICA is particularly involved in the characterisation and valorization part of the recycled carbon fibres in second generation 2.0 semi-products and composites. Carbon fibre composite materials are becoming more common, and their use continues to grow every year. Their recycling is still difficult, but it is nevertheless necessary, both for environmental, economic and legislative reasons at European level.

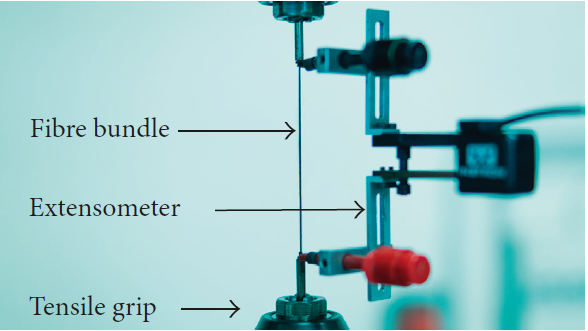

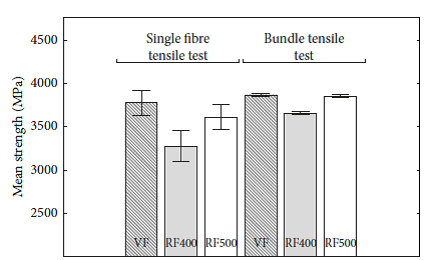

Two theses have been defended at the ICA on this issue: the thesis of Maxime Boulanghien (2014) «Formulation of thermoplastic composites from recycled carbon fibres» and the thesis of Sabrine Jlassi (2019) “Recycled carbon fibre composites: source variability and mechanical performance optimization”. They showed that the performance of the fibres after recycling was not impaired (see Figure 1) and thatA promising industrial route for moderately structural applications was the use of thermoplastic fibres. (see Figure 2).

Within the scope of this joint laboratory, two new technological and scientific problems are currently being pursued (one in the framework of a RAPID DGA project and the other in the CIFRE thesis backed up by a European project) : the development of a process for the production of “fibre yarns” in order to be able to develop more organized and therefore more structural fibrous architecture on the one hand, surface functionalization in-situ in order to offer a surface treatment adapted to the different families of matrices to improve the fibre-matrix adhesion and therefore the properties of the materials.

Figure 1 : Mean strenghs and their 95% confidence intervals obtained by single fibre tensile tests and bubdle tensile tests

Figure 2 :

- a) Non-tissé fibre de carbone recyclé comélé PA6

- b) Pièces réalisée par thermocompression du non tissé comélé PA6

Responsible : Gérard Bernhart