Composite Materials and Structures Group

The MSC group includes 30 permanent researchers (assistant, associate and full professors), close to 45 PhD students, 10 post-doc and project engineers. The group is organized in two research axes: Material Processes and Properties (MaPP) and Structures Impact Modelling Machining (SIMU)

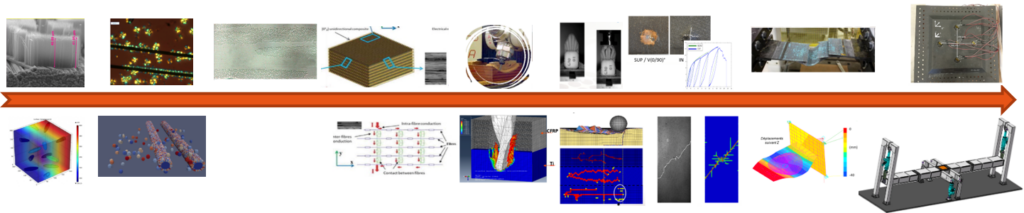

The MSC group’s research focuses on the study of materials and composite structures at various stages of their life cycle:

- • Development, manufacturing and machining.

- • In service mechanical behavior.

- • Repair, reuse and recycling.

The proposed approaches combine experience, model development, and numerical simulation to achieve this.

The applications are mainly, but not exclusively, related to the aeronautical and aerospace sectors.

Group activities :

- • Composite life cycle: from the Manufacturing processes (development, machining, assembly, repair, recycling) to the structure.

- • Materials: fiber reinforced polymers (synthetic or bio composites such as: flax, jute, wood, cork, etc.), ceramic matrix composites, multi-materials.

- • Multi-scale approaches: from nano to macro scale (structure).

- • Multidisciplinary: materials science, solid mechanics, fluid mechanics, etc.

- • Multiphysics approaches: mechanical, physicochemical, thermal, electrical

- • Tests/Calculations: balanced approach between experimentation, modelling, and numerical simulation

Generic scientific methodologies across the group:

- • Experimental identifications of engineering phenomena applied to manufacturing problems, behavior, or damage.

- • Development of original tests for phenomenological understanding, parameter identification, model validation, and numerical simulations.

- • Development of strategies for specific modelling that are representative of the studied physics.

- • Development of multi-scale approaches to composite structures associated with material knowledge.

Group Organization:

Composite Materials Structures (MSC)

Heads: T. Cutard, R. Zitoune

MaPP Axis

Material Processes and Properties

Axis leaders: A. Cantarel, L. Crouzeix

Three scientific themes:

- • Th 1 : Studying, understanding and modelling of multi-physics phenomena in manufacturing processes

- • Th 2: Studying the influence of manufacturing parameters on physical properties on different multi-scale levels

- • Th 3: Digital twins – Contribution to virtual manufacturing

SIMU Axis

Structures Impact Modelling Machining

Axis leaders: O. Dorival, F. Lachaud, S. Marguet

Three scientific themes:

- • Th 1: Damage modelling: damage tolerance

- • Th 2: Relationship between material integrity (manufacturing/machining/repair), environment (humidity / temperature) and the mechanical strength of synthetic and bio sourced composite structures. cale levels

- • Th 3: Virtual testing

Scientific networks:

- AMAC (Association pour les MAtériaux Composites)

- GDR Sciences du bois

- GDR (CMC)2 (Composites à Matrice Céramique : Conception, Modélisation, Caractérisation)

- GDR MIC (MIse en œuvre des Composites et propriétés induites)

- GUB (Groupe Usinage Bois)

- Polynano (Polymères Nanochargés – Matériaux Multifonctionnels)

- Xylomat (un des 6 plateaux de la plateforme Xyloforest)

- Pôle RHYO (Pôle de Recherche sur l’Hydrogène Occitan)

- GDR TAMARYS (interface entre science des matériaux et science des transferts thermiques, transferts radiatifs)

- Défi Clé MIDOC (la Mobilité Intelligente et Durable en OCcitanie)